PP Spun Filter Cartridge

- Made upof silicone free mater alas 100% polypropylene media.

- Providing multiple filtration tone,which produces gradient pore structure.

- The sect ion captureslarger particles v1hile innermost section efficiently & consistent removesmallerparticles.

- Excellentchemicalresistance.

- High dirt holdingcapacity.

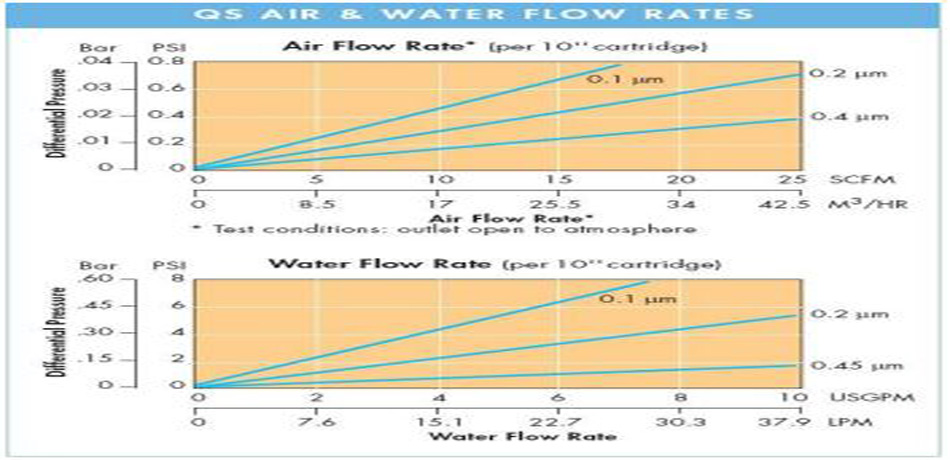

- High flo\Y rate& lo\Y differentialpressure.

- FDA complied polypropylene material

Flow Rate:Standard 16 LPM and jumbo 50 LPM for Raw Water with a Operating pressure 2.S Bar

| Di> [INCH ) | 2.S | 2.S | 2.S | 2.S | 4 | 4 |

| Height (INCH) | 10 | 20 | 30 | 40 | 10 | 20 |